Installation & Maintenance Guide for Cantilever Gate Kits (Ultimate UK Guide)

Browse our full range of external-wheel sliding gate kits: https://mytoolsshop.co.uk/

Request a personalized quote: in**@************co.uk

Contact us for expert guidance on choosing the right sliding gate hardware:+44) ********42

Sliding gate hardware: https://mytoolsshop.co.uk/

Cantilever gate kits are one of the most reliable and low-maintenance solutions for residential and commercial sliding gates in the UK. Ideal for uneven driveways, gravel surfaces, sloping entrances, and high-traffic properties, these trackless systems eliminate the issues commonly found in ground-track sliding gates.

This expert guide explains how to install a cantilever gate kit, how to maintain it for years of smooth operation, and how to avoid common installation problems. Whether you’re a contractor, homeowner, or DIY installer, this is your complete step-by-step resource on cantilever sliding gate installation UK.

Cantilever gate kits: https://mytoolsshop.co.uk/product-category/sliding-gate-kits/cantilever-gate-kit/

1. What You Need Before Installing a Cantilever Gate Kit

Proper preparation ensures long-term reliability. Before installing any cantilever sliding gate kit, confirm the following:

Structural & Site Requirements

- A solid concrete base for the posts and roller carriages

- Accurate measurements of the opening width and runback space

- Sufficient side clearance for the gate to retract fully

- Level checking for support posts

These factors prevent gate sagging, roller damage, and long-term structural weakness. This preparation is key to ensuring your cantilever sliding gate kit is the best cantilever gate system for uneven driveways.

Essential Tools & Equipment

Power drill & masonry bits

Spirit level

Heavy-duty bolts & fixings

Welding tools (if assembling a metal frame)

Outdoor-grade grease

Measuring tape

PPE (gloves, goggles)

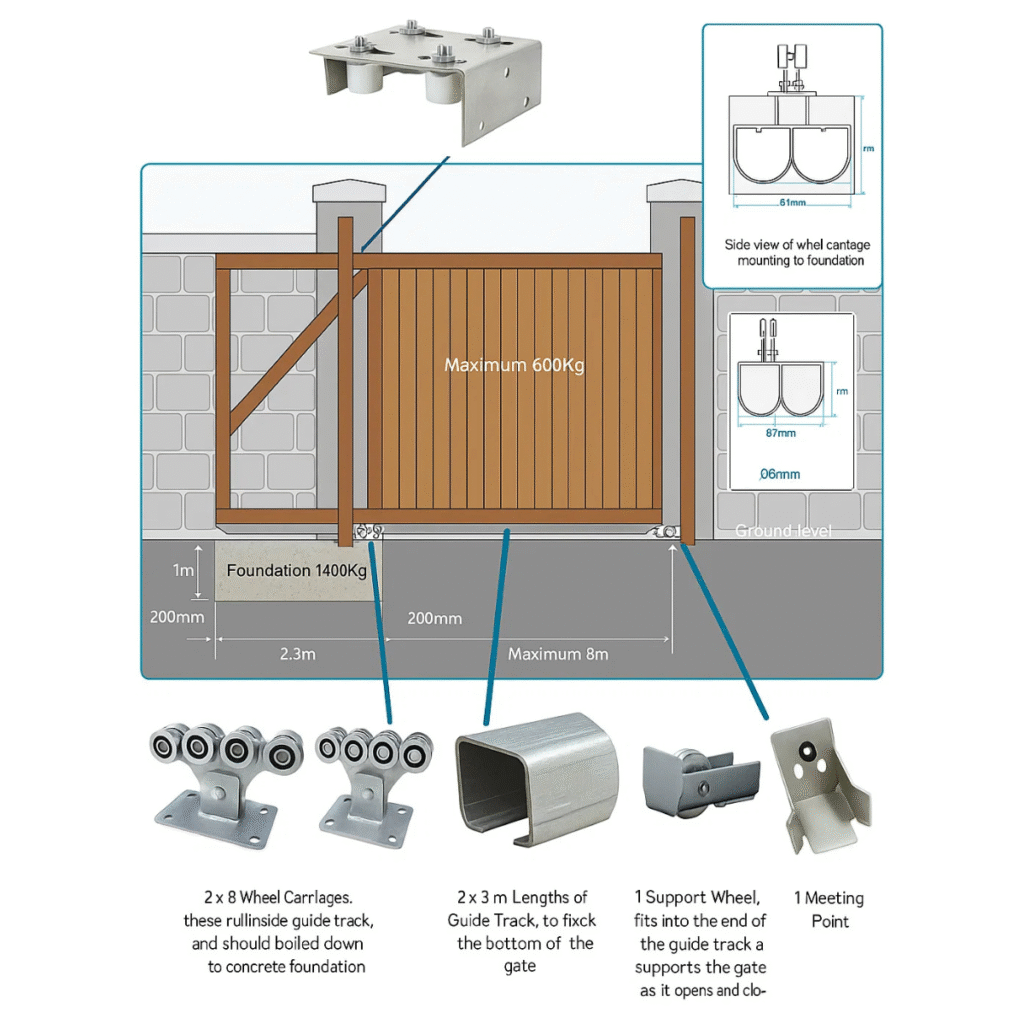

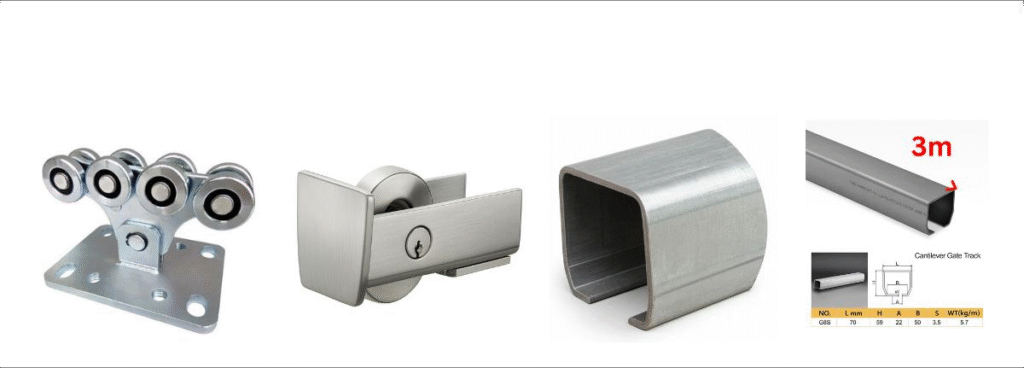

Cantilever Kit Components

A standard sliding gate kit for a cantilever system typically includes:

Cantilever roller carriages

Top guide rollers

Catcher bracket

End stop

Heavy-duty support post

2. Step-by-Step Cantilever Gate Installation (Professional UK Method)

Official gate installation guidance:

https://www.hse.gov.uk/index.htm

The following steps cover the professional method for how to install a cantilever gate kit in the UK.

Step 1 — Build a Strong Concrete Foundation

A cantilever gate places significant weight on its support posts. For UK soil conditions, foundations should generally be 600–800 mm deep. This is the best foundation depth for cantilever gate UK for stability.

Allow curing for 24–48 hours before installation.

Step 2 — Install Main Support and Catcher Posts

Ensure both posts are:

Perfectly vertical

Securely anchored

Directly aligned with the gate path

Misalignment leads to noisy operation, friction, and premature wear. This is a crucial step in fulfilling all UK sliding gate installation requirements.

Step 3 — Mount Cantilever Roller Carriages

Bolt the roller carriages to the foundation. Use a level to guarantee both carriages sit at equal height.

If these rollers are uneven, the gate will:

❌ wobble

❌ drag

❌ scrape

❌ or lean to one side

Step 4 — Position the Gate Frame on the Rollers

Carefully slide the gate onto the rollers. This is usually a two-person job due to the gate’s weight.

Check that:

✔ the gate floats smoothly

✔ the track sits properly in the roller grooves

✔ there is no ground contact

If adjustments are needed, search for “how to adjust cantilever gate rollers.”

Step 5 — Install Top Guide Rollers

The guide rollers must keep the gate steady without pinching it. Leave a 2–4 mm gap between the roller and the gate frame.

Step 6 — Attach Catcher Bracket & End Stop

These components ensure the gate:

- Stops safely

- Stays locked in windy conditions

- Doesn’t slide off rollers

- Remains aligned when fully closed

Step 7 — Final Alignment Test

Open and close the gate several times.

Look for:

✔ smooth motion

✔ no metal-on-metal scraping

✔ consistent clearance

✔ straight alignment

If movement is stiff or noisy, adjust roller height. If you need to know “how to fix a stiff cantilever gate,” roller adjustment is usually the first step.

3. Automation Tips for Cantilever Sliding Gates

If you plan to add a gate motor to your cantilever gate kit:

Choose a sliding gate motor with a higher weight rating than your gate.

Install a rack and pinion system along the bottom rail.

Fit photocells and safety sensors for UK compliance.

Research the “best motor for cantilever sliding gate UK” to ensure reliable automation.

3. Safety & Maintenance Guide — Increase Lifespan & Smooth Operation

Gate Safety & Maintenance:

https://www.hse.gov.uk/safetybulletins/revision-standards-powered-doors.htm

Proper gate maintenance keeps your cantilever sliding gate system performing like new. This is the key to long-lasting gate hardware maintenance.

1. Lubricate Moving Parts (Every 2–3 Months)

Use outdoor-grade grease or a recommended lubricant. Research the “best lubricant for cantilever gate rollers.”

- Lubricate:

- Roller bearings

- Guide rollers

- Hinges

- Motor gear (if automated)

2. Clean Roller Areas & Frame (Monthly)

Even trackless sliding gate guide systems accumulate debris.

Clean:

Roller housings

Gate underside

Motor gear rack

3. Inspect Alignment and Level (Every 6 Months)

Check for:

Sagging

Gate wobbling

Uneven movement

Noisy opening/closing

Adjust roller heights to restore correct alignment. This is a critical step in cantilever gate maintenance tips.

4. Tighten All Fixings (Quarterly)

Outdoor gates naturally loosen due to vibration and UK weather.

Check:

Roller bolts

Guide roller brackets

Post fixings

End stop bolts

5. Check for Rust or Paint Damage

- Steel frames should be kept rust-free using:

- Galvanized coating

- Outdoor paint

- Touch-up paint for scratches

- This prevents degradation of your heavy-duty cantilever gate support.

5. When to Call a Professional Gate Installer

Hire an expert if:

- Your driveway is heavily sloped

- Gate weight exceeds 300–500 kg

- Posts are unstable

- Motor isn’t responding

- You see sudden misalignment

Final Conclusion

Cantilever gate kits provide one of the most durable, smooth, and low-maintenance sliding gate solutions available in the UK. With proper gate installation and regular care, these gates deliver years of reliable performance — even on sloped, uneven, or debris-prone driveways.

Follow this step-by-step DIY cantilever gate setup guide, implement the maintenance routine, and enjoy a long-lasting cantilever sliding gate system that operates smoothly every day.